DEFENSE APPLICATION (ARMOUR STEEL)

An Armour Plate with High Hardness and Excellent Ballistic resistance properties, strength and workability. it is guaranteed to keep you safe and secure.

HIGH NITROGEN STEEL (HNS)

Thickness: 3mm-80mm

Chemical Composition

|

%C (max) |

%Mn (max) |

%S (max) |

%P (max) |

%Si (max) |

%Cr (max) |

%N (max) |

| Min. |

- |

21.0 |

- |

- |

- |

17.5 |

0.5 |

| Max. |

0.1 |

24.0 |

0.015 |

0.060 |

1.0 |

20.0 |

0.7 |

Mechanical Properties

| Thickness (mm) |

Y.S (MPa, min) |

U.T.S (MPa, min) |

%EI, min |

Impact Toughness (L, RT), J Min |

| < 10 |

950-1250 |

1000-1300 |

15 |

- |

| 10 to < 20 |

750-1050 |

900-1150 |

30 |

150 |

| 20 to 50 |

700-850 |

900-1100 |

30 |

200 |

HIGH NITROGEN STEEL (HNS)ARMOUR WITH MINIMUM GUARANTEE HARDNESS OF 500 HB (JD-1)

Thickness: 3mm-80mm

Chemical Composition

| %C (max) |

%Mn (max) |

%S (max) |

%P (max) |

%Si (max) |

%Cr (max) |

%N (max) |

| 0.32 |

1.5 |

0.010 |

0.5 |

2.2 |

1.0 |

1.0 |

Mechanical Properties

| Y.S (MPa, min) |

U.T.S (MPa, min) |

%EI, min |

Hardness (HB) |

Charpy Impact Toughness (J/ -40°C) Min* |

| 1400 |

1550 |

8 |

500-550 |

35 |

ARMOUR WITH MINIMUM GUARANTEE HARDNESS OF 550 HB (JD-1M)

Thickness: 5mm-80mm

Chemical Composition

| %C (max) |

%Mn (max) |

%S (max) |

%P (max) |

%Si (max) |

%Ni (max) |

%Cr (max) |

%Mo (max) |

| 0.4 |

1.5 |

0.010 |

0.015 |

0.5 |

2.5 |

1.5 |

1.0 |

Mechanical Properties

| Y.S (MPa, min) |

U.T.S (MPa, min) |

%EI, min |

Hardness (HB) |

Charpy Impact Toughness (J/ -40°C) Min* |

| 1500 |

1700 |

6 |

550-580 |

12 |

ABRASION RESISTANT/WEAR PLATE

These are an advanced range of higher abrasion and wear resistant plates designed as per hardness level. Produced through cutting-edge Quenched or Quenched & tempered process. Products possess an exceptional combination of higher hardness & toughness, optimally designed chemistry, coupled with superior dimensional tolerances which helps in ease of fabrication. Wear-resistant Steel Plate products for application in Yellow Goods & Mining Equipment (Dump Body Trucks, Bulldozer Buckets, Crushers, Mixers, Loaders, Shovels) and Material Handling Equipment (Chutes, Hoppers, Body Liners).

Dimension Range

| Property |

Grade 1 |

Grade 2 |

Grade 3 |

| Thickness |

8-100mm |

8-100mm |

8-100mm |

| Width |

1500-4800mm |

1500-4800mm |

1500-4800mm |

| Hardness |

360 BHN Min (Typical 360-450) |

425 BHN Min (Typical 425-500) |

470 BHN Min (Typical 470-550) |

| YS (MPa Min) |

1100 |

1150 |

1250 |

| UTS (MPa Min) |

1250 |

1300 |

1600 |

| EL (MPa Min) |

12% |

12% |

10% |

| Impact-/Toughness Min |

25J(avg), 20J(ind)J at (-40)°C |

25J(avg), 20J(ind)J at (-40)°C |

25J(avg), 20J(ind)J at (-40)°C |

Dimension Range

These plates are very high strength structural steel and can result in greater load-carrying capacities and lighter structures when used in place of conventional structural steels.

Mechanical Properties of S690QL:

| Nominal thickness (mm) |

Minimum yeild strength (MPa) |

Tensile strength (MPa) |

Minimum Elongation (%) |

Minimum Impact Energy (J) @ -40°C |

| 3<= 50 |

690 |

770-940 |

14 |

30 longitudinal or 27 transverse |

| > 50 <= 100 |

650 |

760-930 |

14 |

30 longitudinal or 27 transverse |

| > 100 <= 150 |

630 |

710-900 |

14 |

30 longitudinal or 27 transverse |

Sheet piles are thin interlocking steel sheets used to construct a continuous barrier in the ground to retain earth/water. Interlock is typically achieved by clutching the edge of one pile into the previous pile. Vibratory hammers are used to install sheet piles.

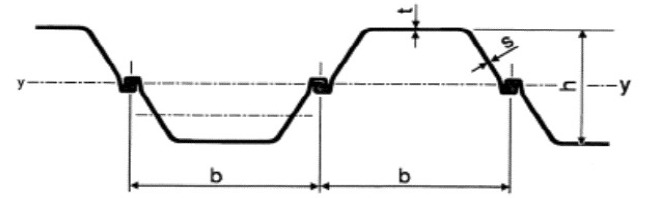

U-TYPE SHEET PILE

The Sheet Pile cross-sectional performance values

| Dimensions |

Per Steel Sheet Pile |

Per Each Meter of Wall Width |

| Effective Width (W) [mm] |

Effective Height (H) [mm] |

Thickness (t) [mm] |

Cross Section (× 10-4 m²) |

Geometrical Moment of Inertia (× 10-8 m⁴) |

Section Modulus (× 10-6 m³) |

Unit Weight (kg/m²) |

Section modulus × 10-6(m3/m) |

Geometrical moment of inertia ×10-8 (m4/m) |

Unit Weight (kg/m) |

| 400 |

170 |

15.5 |

96.99 |

4670 |

362 |

76.1 |

2270 |

38600 |

190 |

The mechanical properties of Sheet Pile

| MECHANICAL PROPERTIES |

| YIELD STRENGTH(N/mm2) |

TENSILE STRENGTH(N/mm2) |

ELONGATION(%) |

|

410 Min

|

540 Min

|

20 Min

|

Section product range

| Section |

Section modulus (Wy cm³/m) |

Weight (kg/m²) |

Weight (kg/m) |

Moment of Inertia (Iy cm⁴/m) |

Back Thickness (t mm) |

Web Thickness (s mm) |

Wall Height (h mm) |

Section Width (b mm) |

| HOESCH 1208 | 1.301 | 1.000 | 73.2 | 22.995 | 8.5 | 8.5 | 354 | 770 |

| HOESCH 1308 | 1.357 | 1.043 | 76.6 | 24.013 | 9.0 | 9.0 | 354 | 770 |

| HOESCH 1408 | 1.412 | 1.084 | 80.1 | 25.030 | 9.5 | 9.5 | 354 | 770 |

| HOESCH 1707 | 1.731 | 1.209 | 104.8 | 36.304 | 8.5 | 8.5 | 420 | 700 |

| HOESCH 1807 | 1.804 | 1.261 | 109.5 | 37.894 | 9.0 | 9.0 | 420 | 700 |

| HOESCH 2007 | 1.951 | 1.366 | 119.4 | 41.076 | 10.0 | 10.0 | 421 | 700 |

| HOESCH 2607 | 2.606 | 1.824 | 146.5 | 57.329 | 12.0 | 12.0 | 421 | 700 |

| HOESCH 2807 | 2.779 | 1.945 | 157.0 | 61.279 | 13.0 | 13.0 | 421 | 700 |

| HOESCH 3607 | 3.600 | 2.512 | 118.1 | 95.158 | 12.5 | 12.5 | 501 | 700 |

| HOESCH 3807 | 3.800 | 2.654 | 124.5 | 100.374 | 13.0 | 13.0 | 501 | 700 |

| HOESCH 4007 | 3.999 | 2.799 | 131.2 | 105.714 | 14.0 | 14.0 | 501 | 700 |

| HOESCH 4807 | 4.760 | 3.309 | 156.1 | 120.667 | 14.5 | 14.5 | 509 | 700 |

| HOESCH 5007 | 4.959 | 3.454 | 164.0 | 125.966 | 24.5 | 16.0 | 509 | 700 |