Special Steel

Thickness: 3mm-80mm

An Armour Plate with High Hardness and Excellent Ballistic resistance properties, strength and workability. it is guaranteed to keep you safe and secure.

Chemical Composition

| %C (max) | %Mn (max) | %S (max) | %P (max) | %Si (max) | %Cr (max) | %N (max) | |

|---|---|---|---|---|---|---|---|

| Min. | - | 21.0 | - | - | - | 17.5 | 0.5 |

| Max. | 0.1 | 24.0 | 0.015 | 0.060 | 1.0 | 20.0 | 0.7 |

Mechanical Properties

| Thickness (mm) | Y.S (MPa, min) | U.T.S (MPa, min) | %Elongation, min | Impact Toughness (L, RT), J Min |

|---|---|---|---|---|

| < 10 | 950–1250 | 1000–1300 | 15 | – |

| 10 to < 20 | 750–1050 | 900–1150 | 30 | 150 |

| 20 to 50 | 700–850 | 900–1100 | 30 | 200 |

Thickness: 3mm-80mm

Chemical Composition

| %C (max) | %Mn (max) | %S (max) | %P (max) | %Si (max) | %Cr (max) | %N (max) |

|---|---|---|---|---|---|---|

| 0.32 | 1.5 | 0.010 | 0.5 | 2.2 | 1.0 | 1.0 |

Mechanical Properties

| Y.S (MPa, min) | U.T.S (MPa, min) | %EI, min | Hardness (HB) | Charpy Impact Toughness (J/ -40°C) Min* |

|---|---|---|---|---|

| 1400 | 1550 | 8 | 500–550 | 35 |

Thickness: 5mm-80mm

Chemical Composition

| %C (max) | %Mn (max) | %S (max) | %P (max) | %Si (max) | %Cr (max) | %N (max) |

|---|---|---|---|---|---|---|

| 0.32 | 1.5 | 0.010 | 0.5 | 2.2 | 1.0 | 1.0 |

Mechanical Properties

| Y.S (MPa, min) | U.T.S (MPa, min) | %EI, min | Hardness (HB) | Charpy Impact Toughness (J/ -40°C) Min* |

|---|---|---|---|---|

| 1400 | 1550 | 8 | 500–550 | 35 |

These are an advanced range of higher abrasion and wear resistant plates designed as per hardness level. Produced through cutting-edge Quenched or Quenched & tempered process. Products possess an exceptional combination of higher hardness & toughness, optimally designed chemistry, coupled with superior dimensional tolerances which helps in ease of fabrication. Wear-resistant Steel Plate products for application in Yellow Goods & Mining Equipment (Dump Body Trucks, Bulldozer Buckets, Crushers, Mixers, Loaders, Shovels) and Material Handling Equipment (Chutes, Hoppers, Body Liners).

Dimension Range

| Property | Grade 1 | Grade 2 | Grade 3 |

|---|---|---|---|

| Thickness | 8-100mm | 8-100mm | 8-100mm |

| Width | 1500-4800mm | 1500-4800mm | 1500-4800mm |

| Hardness | 360 BHN Min (Typical 360-450) | 425 BHN Min (Typical 425-500) | 470 BHN Min (Typical 470-550) |

| YS (MPa Min) | 1100 | 1150 | 1250 |

| UTS (MPa Min) | 1250 | 1300 | 1600 |

| EL (Min %) | 12% | 12% | 10% |

| Impact/Toughness Min | 25J(avg), 20J(ind) at (-40)°C | 25J(avg), 20J(ind) at (-40)°C | 25J(avg), 20J(ind) at (-40)°C |

These plates are very high strength structural steel and can result in greater load-carrying capacities and lighter structures when used in place of conventional structural steel.

Mechanical Properties of S690QL:

| Nominal Thickness (mm) | Minimum Yield Strength (MPa) | Tensile Strength (MPa) | Minimum Elongation (%) | Minimum Impact Energy (J) @ -40°C |

|---|---|---|---|---|

| 3 ≤ t ≤ 50 | 690 | 770–940 | 14 | 30 longitudinal or 27 transverse |

| > 50 ≤ 100 | 650 | 760–930 | 14 | 30 longitudinal or 27 transverse |

| > 100 ≤ 150 | 630 | 710–900 | 14 | 30 longitudinal or 27 transverse |

Sheet piles are thin interlocking steel sheets used to construct a continuous barrier in the ground to retain earth/water. Interlock is typically achieved by clutching the edge of one pile into the previous pile. Vibratory hammers are used to install sheet piles.

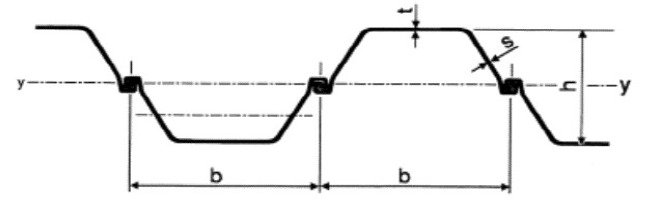

U-TYPE SHEET PILE

Sheet Pile Cross-Sectional Performance Values

| Dimensions | Per Steel Sheet Pile | Per Each Meter of Wall Width | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Effective Width (W) [mm] | Effective Height (H) [mm] | Thickness (t) [mm] | Cross Section (×10⁻⁴ m²) | Moment of Inertia (×10⁻⁸ m⁴) | Section Modulus (×10⁻⁶ m³) | Unit Weight (kg/m²) | Section Modulus (×10⁻⁶ m³/m) | Moment of Inertia (×10⁻⁸ m⁴/m) | Unit Weight (kg/m) |

| 400 | 170 | 15.5 | 96.99 | 4670 | 362 | 76.1 | 2270 | 38600 | 190 |

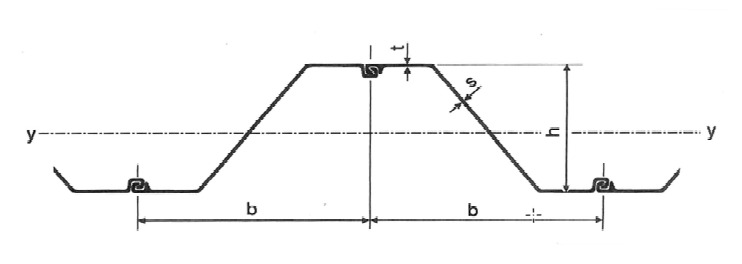

Section product range

| Section | Section Modulus (Wy cm³/m) | Weight (kg/m²) | Weight (kg/m) | Moment of Inertia (Iy cm⁴/m) | Back Thickness (t mm) | Web Thickness (s mm) | Wall Height (h mm) | Section Width (b mm) |

|---|---|---|---|---|---|---|---|---|

| HOESCH 1208 | 1.301 | 1.000 | 73.2 | 22.995 | 8.5 | 8.5 | 354 | 770 |

| HOESCH 1308 | 1.357 | 1.043 | 76.6 | 24.013 | 9.0 | 9.0 | 354 | 770 |

| HOESCH 1408 | 1.412 | 1.084 | 80.1 | 25.030 | 9.5 | 9.5 | 354 | 770 |

| HOESCH 1707 | 1.731 | 1.209 | 104.8 | 36.304 | 8.5 | 8.5 | 420 | 700 |

| HOESCH 1807 | 1.804 | 1.261 | 109.5 | 37.894 | 9.0 | 9.0 | 420 | 700 |

| HOESCH 2007 | 1.951 | 1.366 | 119.4 | 41.076 | 10.0 | 10.0 | 421 | 700 |

| HOESCH 2607 | 2.606 | 1.824 | 146.5 | 57.329 | 12.0 | 12.0 | 421 | 700 |

| HOESCH 2807 | 2.779 | 1.945 | 157.0 | 61.279 | 13.0 | 13.0 | 421 | 700 |

| HOESCH 3607 | 3.600 | 2.512 | 118.1 | 95.158 | 12.5 | 12.5 | 501 | 700 |

| HOESCH 3807 | 3.800 | 2.654 | 124.5 | 100.374 | 13.0 | 13.0 | 501 | 700 |

| HOESCH 4007 | 3.999 | 2.799 | 131.2 | 105.714 | 14.0 | 14.0 | 501 | 700 |

| HOESCH 4807 | 4.760 | 3.309 | 156.1 | 120.667 | 14.5 | 14.5 | 509 | 700 |

| HOESCH 5007 | 4.959 | 3.454 | 164.0 | 125.966 | 24.5 | 16.0 | 509 | 700 |

We are always ready to help you and answer your questions